focus on electric meter manufacturing,

with technical support R&D team,

have more than 200 staffs,

modern production lines

| Availability: | |

|---|---|

| Quantity: | |

DDS986

Tepsung

9028301300

Adopts a dual-core energy metering chip (imported from Texas Instruments) with a measurement accuracy class of Class 0.5S, strictly complying with IEC 62053-22 standard—error range is ≤±0.5% under rated load (10%~100% of rated current) and ≤±1% under light load (5%~10% of rated current), ensuring accurate recording of even micro-power consumption (e.g., standby power of household appliances).

Equipped with a 16-bit analog-to-digital converter (ADC) for real-time sampling of voltage and current signals (sampling frequency up to 10kHz), avoiding measurement deviations caused by signal delay, and supporting accurate 计量 of unstable power sources (e.g., power supply with frequent voltage fluctuations).

Supports dual data output modes: RS485 communication interface (compatible with Modbus-RTU protocol) for remote real-time data transmission (transmission rate adjustable: 9600~115200 bps) and manual button query (one-key switch between active energy, voltage, current, power factor, and operating time).

2.2-inch ultra-clear LCD screen with constant backlight (brightness adjustable in 3 levels) and large font display (energy data font size 12mm), ensuring clear visibility even in strong light or dim environments; screen automatically records the maximum power consumption of the day (reset at 00:00 daily) for load analysis.

Shell uses PC+ABS composite material (flame retardant grade V0) with a reinforced structure, capable of withstanding impact force up to 50N and operating in -30℃~75℃ extreme temperature environments, suitable for harsh conditions such as outdoor distribution boxes and basement workshops.

Built-in 6-level protection: overvoltage (cutoff when voltage >270V), overcurrent (protection triggered when current >1.5x rated current), short-circuit (self-recovering fuse with response time <0.1s), reverse wiring (no power supply and no wrong measurement), electromagnetic interference (anti-EMI level Class B), and dustproof moisture-proof (protection grade IP42).

Rated Voltage: 220V AC (50Hz/60Hz, dual-frequency compatible)

Rated Current Range: 10A~80A (wide-range measurement, no need for current transformer)

Maximum Measurable Current: 100A (short-term, continuous operation ≤30 minutes)

Voltage Measurement Range: 176V~286V AC

Power Factor Measurement Range: 0.2 (lagging)~1.0 (leading)

Active Energy Measurement Unit: kWh (minimum resolution 0.001kWh)

Accuracy Class: Class 0.5S (IEC 62053-22)

Data Storage: Non-volatile memory (NVM) stores 24 months of monthly cumulative energy records (data retention ≥10 years without power supply)

Communication Distance: RS485 maximum transmission distance 1200 meters (when using shielded twisted pair)

Display Update Interval: 1 second (real-time synchronization with sampling data)

Installation Dimensions: 19mm (thickness) × 92mm (height) × 68mm (width)

Mounting Type: Standard 35mm DIN rail (compatible with DIN EN 50022 standard)

Terminal Compatibility: 10mm²~35mm² copper core wires (screw-type terminals with anti-loosening design)

Storage Temperature: -40℃~85℃

Relative Humidity: ≤98% (non-condensing, no dew formation)

Vibration Resistance: Complies with IEC 60068-2-6 standard (10~55Hz, acceleration 10m/s²)

Parameter Matching Check: Confirm that the on-site power supply voltage (220V AC) and maximum load current (≤80A) match the meter’s rated parameters; if the load exceeds 80A, replace with a higher-current model to avoid damage.

Meter Inspection: Check the meter’s nameplate (confirm model, accuracy class, and rated parameters), shell (no cracks or deformation), and terminals (no looseness or oxidation); power on temporarily (connect to 220V AC) to verify if the LCD screen displays normally.

Tool & Material Preparation: Prepare PH2 cross screwdriver, wire stripper (stripping length 9~11mm), multimeter (for voltage/current detection), and insulation tape (for processing wire ends with burrs).

Meter Fixing: Open the distribution box, clean the 35mm DIN rail (remove dust, rust, or debris), align the meter’s DIN rail clamping slot with the rail, push upward until a "click" sound is heard (confirm firm fixation; pull gently to check if it is loose).

Wiring Operation: According to the wiring diagram on the meter’s inner cover: connect the live wire (L) to the "Input L" terminal, neutral wire (N) to "Input N" terminal; connect the load’s live wire to "Output L" terminal, load’s neutral wire to "Output N" terminal. Tighten the terminal screws with a torque of 3.0N·m (use a torque screwdriver for accuracy to avoid poor contact or terminal damage).

Wiring Correctness Detection: Use a multimeter to measure the voltage between "Input L" and "Input N" (should be 220V±10%), and check if there is a short circuit between terminals (no continuity between L and N terminals).

Power-On Activation: Close the distribution box, turn on the main switch, and confirm that the LCD screen displays "220V" (voltage), "0A" (current, no load), and "0.000kWh" (energy); if there is a load, check if the current and power values are consistent with the actual load (e.g., 1000W appliance should display ~4.5A current).

Data Query: Press the "Mode" button to cycle through and view active energy (total), monthly energy (last 24 months), real-time voltage/current, power factor, and operating time; long-press the "Reset" button (3 seconds) to clear the "daily maximum power" record (cannot clear total energy to prevent tampering).

Remote Monitoring Setup (Optional): Connect the meter’s RS485 interface to a smart gateway (using shielded twisted pair), set the meter’s address (1~247) and baud rate (consistent with the gateway) via the gateway’s configuration software, then realize remote data viewing and historical curve analysis through a computer or mobile app.

Regular Maintenance: Every 6 months, open the distribution box to check the meter’s wiring (no looseness or overheating marks) and clean the LCD screen (wipe with a dry soft cloth); every 2 years, contact a professional organization for accuracy calibration (to maintain Class 0.5S accuracy).

Troubleshooting: If the screen shows "Err-01" (overvoltage), turn off the power immediately, check the power supply voltage, and restart after the voltage returns to normal; if "Err-02" (overcurrent) is displayed, reduce the load current (e.g., turn off high-power appliances) and reset by pressing the "Reset" button.

Suitable for high-end residential communities, villas, and houses with high requirements for energy measurement accuracy (e.g., households that focus on energy saving and need to calculate standby power consumption of appliances). The Class 0.5S accuracy can accurately record the power consumption of small-power devices (e.g., 5W router standby power, 10W night light), helping users optimize energy usage habits (e.g., turn off unused appliances to save electricity).

Applicable to rental houses where landlords and tenants pay attention to fair electricity fee calculation: the meter’s non-volatile memory stores historical energy records (cannot be tampered with), avoiding disputes caused by inaccurate measurement; tenants can query real-time power consumption to control costs.

Used in small and medium-sized commercial venues such as supermarkets, restaurants, and office buildings: the RS485 remote monitoring function allows managers to view the power consumption of each area (e.g., supermarket freezer area, restaurant kitchen, office workstation) in real time, identify high-energy-consuming equipment, and formulate energy-saving plans (e.g., replace old refrigerators with energy-efficient models).

Suitable for chain stores (e.g., convenience stores, clothing stores) with centralized energy management needs: multiple meters can be connected to the headquarters’ energy management system, realizing unified monitoring of power consumption across all stores, comparing energy efficiency between stores, and promoting energy-saving

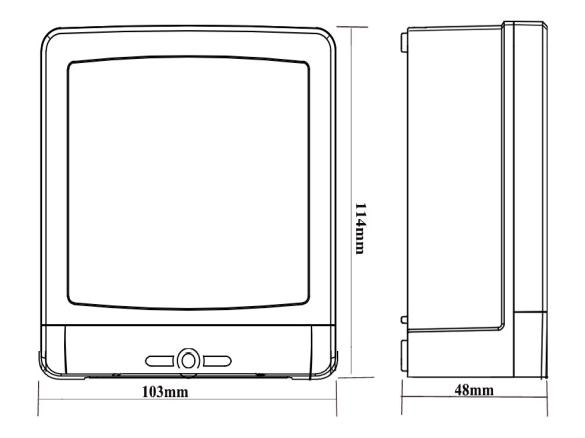

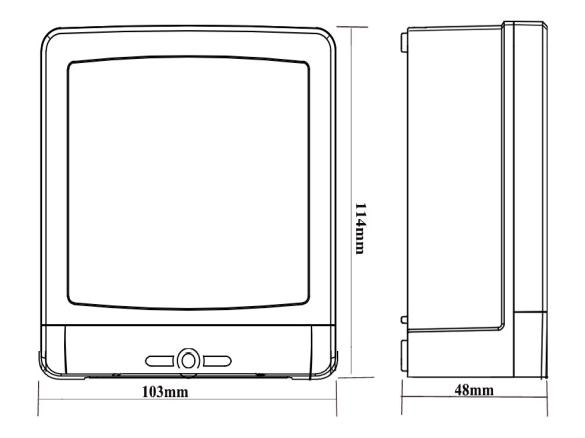

Outer and mounting dimension

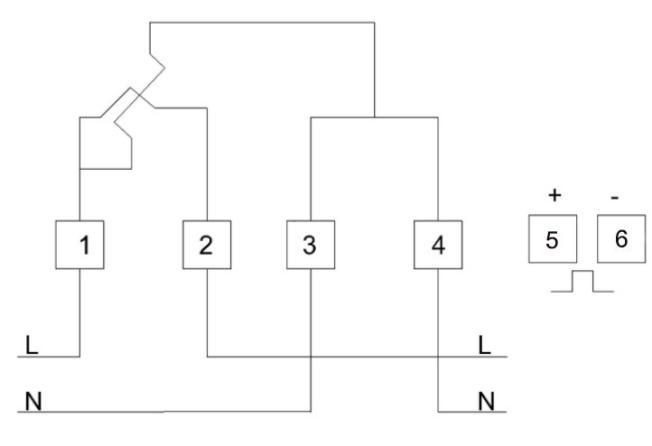

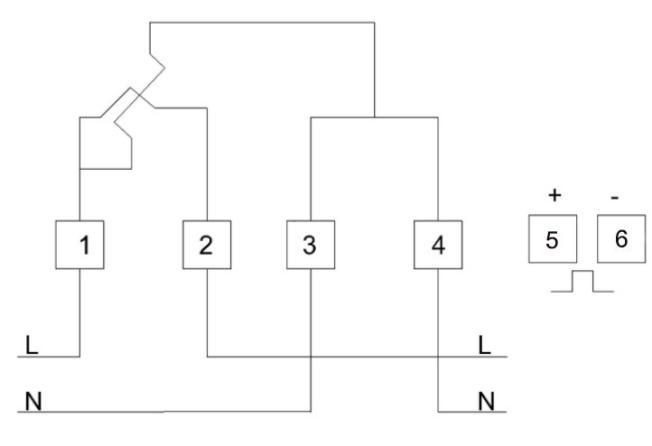

Wiring diagram

Adopts a dual-core energy metering chip (imported from Texas Instruments) with a measurement accuracy class of Class 0.5S, strictly complying with IEC 62053-22 standard—error range is ≤±0.5% under rated load (10%~100% of rated current) and ≤±1% under light load (5%~10% of rated current), ensuring accurate recording of even micro-power consumption (e.g., standby power of household appliances).

Equipped with a 16-bit analog-to-digital converter (ADC) for real-time sampling of voltage and current signals (sampling frequency up to 10kHz), avoiding measurement deviations caused by signal delay, and supporting accurate 计量 of unstable power sources (e.g., power supply with frequent voltage fluctuations).

Supports dual data output modes: RS485 communication interface (compatible with Modbus-RTU protocol) for remote real-time data transmission (transmission rate adjustable: 9600~115200 bps) and manual button query (one-key switch between active energy, voltage, current, power factor, and operating time).

2.2-inch ultra-clear LCD screen with constant backlight (brightness adjustable in 3 levels) and large font display (energy data font size 12mm), ensuring clear visibility even in strong light or dim environments; screen automatically records the maximum power consumption of the day (reset at 00:00 daily) for load analysis.

Shell uses PC+ABS composite material (flame retardant grade V0) with a reinforced structure, capable of withstanding impact force up to 50N and operating in -30℃~75℃ extreme temperature environments, suitable for harsh conditions such as outdoor distribution boxes and basement workshops.

Built-in 6-level protection: overvoltage (cutoff when voltage >270V), overcurrent (protection triggered when current >1.5x rated current), short-circuit (self-recovering fuse with response time <0.1s), reverse wiring (no power supply and no wrong measurement), electromagnetic interference (anti-EMI level Class B), and dustproof moisture-proof (protection grade IP42).

Rated Voltage: 220V AC (50Hz/60Hz, dual-frequency compatible)

Rated Current Range: 10A~80A (wide-range measurement, no need for current transformer)

Maximum Measurable Current: 100A (short-term, continuous operation ≤30 minutes)

Voltage Measurement Range: 176V~286V AC

Power Factor Measurement Range: 0.2 (lagging)~1.0 (leading)

Active Energy Measurement Unit: kWh (minimum resolution 0.001kWh)

Accuracy Class: Class 0.5S (IEC 62053-22)

Data Storage: Non-volatile memory (NVM) stores 24 months of monthly cumulative energy records (data retention ≥10 years without power supply)

Communication Distance: RS485 maximum transmission distance 1200 meters (when using shielded twisted pair)

Display Update Interval: 1 second (real-time synchronization with sampling data)

Installation Dimensions: 19mm (thickness) × 92mm (height) × 68mm (width)

Mounting Type: Standard 35mm DIN rail (compatible with DIN EN 50022 standard)

Terminal Compatibility: 10mm²~35mm² copper core wires (screw-type terminals with anti-loosening design)

Storage Temperature: -40℃~85℃

Relative Humidity: ≤98% (non-condensing, no dew formation)

Vibration Resistance: Complies with IEC 60068-2-6 standard (10~55Hz, acceleration 10m/s²)

Parameter Matching Check: Confirm that the on-site power supply voltage (220V AC) and maximum load current (≤80A) match the meter’s rated parameters; if the load exceeds 80A, replace with a higher-current model to avoid damage.

Meter Inspection: Check the meter’s nameplate (confirm model, accuracy class, and rated parameters), shell (no cracks or deformation), and terminals (no looseness or oxidation); power on temporarily (connect to 220V AC) to verify if the LCD screen displays normally.

Tool & Material Preparation: Prepare PH2 cross screwdriver, wire stripper (stripping length 9~11mm), multimeter (for voltage/current detection), and insulation tape (for processing wire ends with burrs).

Meter Fixing: Open the distribution box, clean the 35mm DIN rail (remove dust, rust, or debris), align the meter’s DIN rail clamping slot with the rail, push upward until a "click" sound is heard (confirm firm fixation; pull gently to check if it is loose).

Wiring Operation: According to the wiring diagram on the meter’s inner cover: connect the live wire (L) to the "Input L" terminal, neutral wire (N) to "Input N" terminal; connect the load’s live wire to "Output L" terminal, load’s neutral wire to "Output N" terminal. Tighten the terminal screws with a torque of 3.0N·m (use a torque screwdriver for accuracy to avoid poor contact or terminal damage).

Wiring Correctness Detection: Use a multimeter to measure the voltage between "Input L" and "Input N" (should be 220V±10%), and check if there is a short circuit between terminals (no continuity between L and N terminals).

Power-On Activation: Close the distribution box, turn on the main switch, and confirm that the LCD screen displays "220V" (voltage), "0A" (current, no load), and "0.000kWh" (energy); if there is a load, check if the current and power values are consistent with the actual load (e.g., 1000W appliance should display ~4.5A current).

Data Query: Press the "Mode" button to cycle through and view active energy (total), monthly energy (last 24 months), real-time voltage/current, power factor, and operating time; long-press the "Reset" button (3 seconds) to clear the "daily maximum power" record (cannot clear total energy to prevent tampering).

Remote Monitoring Setup (Optional): Connect the meter’s RS485 interface to a smart gateway (using shielded twisted pair), set the meter’s address (1~247) and baud rate (consistent with the gateway) via the gateway’s configuration software, then realize remote data viewing and historical curve analysis through a computer or mobile app.

Regular Maintenance: Every 6 months, open the distribution box to check the meter’s wiring (no looseness or overheating marks) and clean the LCD screen (wipe with a dry soft cloth); every 2 years, contact a professional organization for accuracy calibration (to maintain Class 0.5S accuracy).

Troubleshooting: If the screen shows "Err-01" (overvoltage), turn off the power immediately, check the power supply voltage, and restart after the voltage returns to normal; if "Err-02" (overcurrent) is displayed, reduce the load current (e.g., turn off high-power appliances) and reset by pressing the "Reset" button.

Suitable for high-end residential communities, villas, and houses with high requirements for energy measurement accuracy (e.g., households that focus on energy saving and need to calculate standby power consumption of appliances). The Class 0.5S accuracy can accurately record the power consumption of small-power devices (e.g., 5W router standby power, 10W night light), helping users optimize energy usage habits (e.g., turn off unused appliances to save electricity).

Applicable to rental houses where landlords and tenants pay attention to fair electricity fee calculation: the meter’s non-volatile memory stores historical energy records (cannot be tampered with), avoiding disputes caused by inaccurate measurement; tenants can query real-time power consumption to control costs.

Used in small and medium-sized commercial venues such as supermarkets, restaurants, and office buildings: the RS485 remote monitoring function allows managers to view the power consumption of each area (e.g., supermarket freezer area, restaurant kitchen, office workstation) in real time, identify high-energy-consuming equipment, and formulate energy-saving plans (e.g., replace old refrigerators with energy-efficient models).

Suitable for chain stores (e.g., convenience stores, clothing stores) with centralized energy management needs: multiple meters can be connected to the headquarters’ energy management system, realizing unified monitoring of power consumption across all stores, comparing energy efficiency between stores, and promoting energy-saving

Outer and mounting dimension

Wiring diagram

Type | 1 Phase 2 Wire |

Connection | Bottom connected |

Voltage | AC220V,230V,240V |

Basic current(Ib) | 5A,10A,15A,20A,30A |

Max current(Imax) | 100A |

Starting current | 0.04%Ib |

Frequency | 50Hz,60Hz |

Accuracy | Class 1.0 |

Operating temperature | ~25℃~70℃ |

Display | Digital or Analog type |

Size | short terminal cover: 103mm(width)*48mm(depth)*114mm(height) long terminal cover: 157mm(width)*48mm(depth)*114mm(height) |

weight | 0.4kg |

Package | Inner box and carton box |

Customized support(OEM) | Yes |

Type | 1 Phase 2 Wire |

Connection | Bottom connected |

Voltage | AC220V,230V,240V |

Basic current(Ib) | 5A,10A,15A,20A,30A |

Max current(Imax) | 100A |

Starting current | 0.04%Ib |

Frequency | 50Hz,60Hz |

Accuracy | Class 1.0 |

Operating temperature | ~25℃~70℃ |

Display | Digital or Analog type |

Size | short terminal cover: 103mm(width)*48mm(depth)*114mm(height) long terminal cover: 157mm(width)*48mm(depth)*114mm(height) |

weight | 0.4kg |

Package | Inner box and carton box |

Customized support(OEM) | Yes |